Inlet Skimmer

ESI INLET SKIMMER

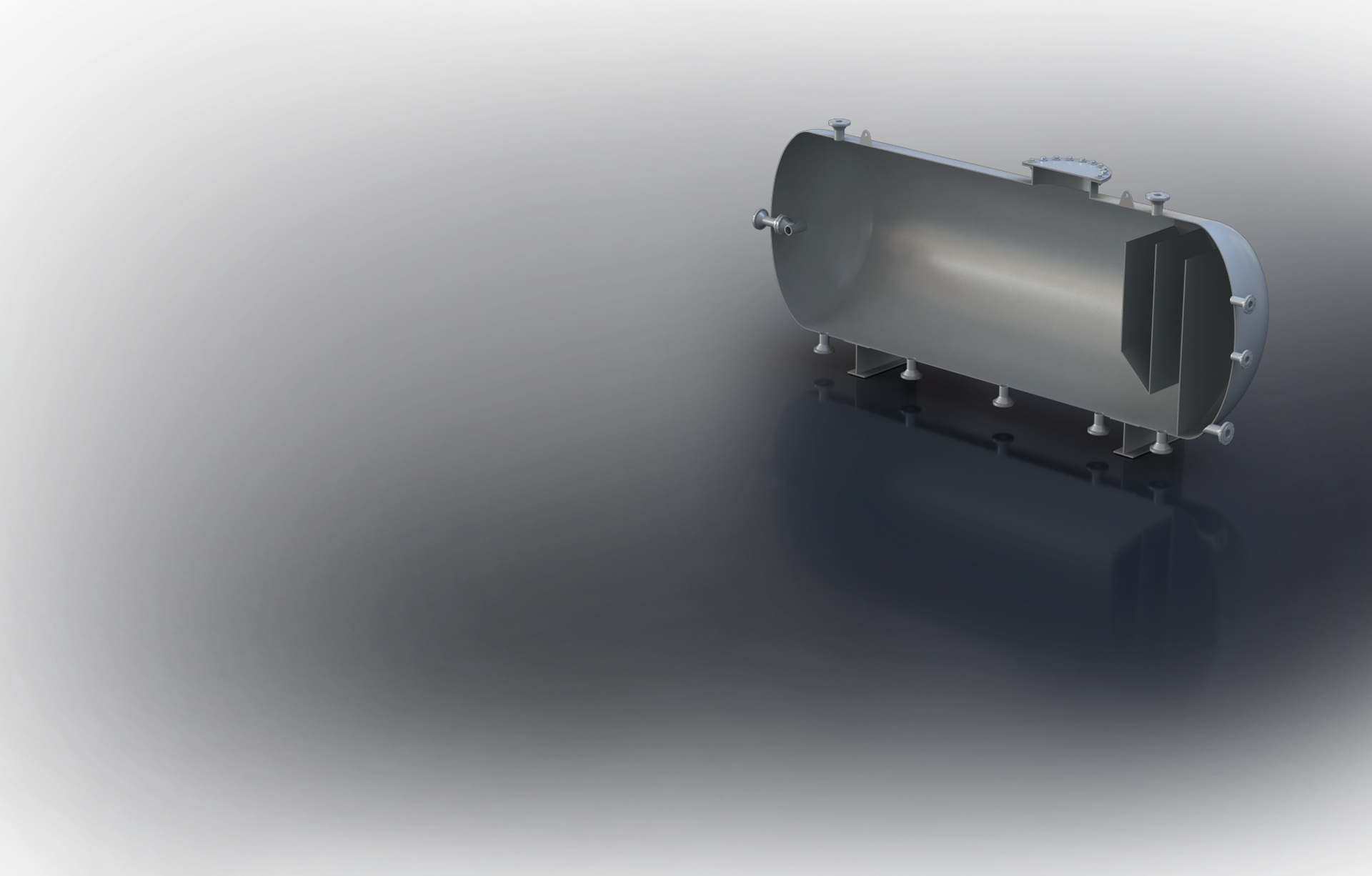

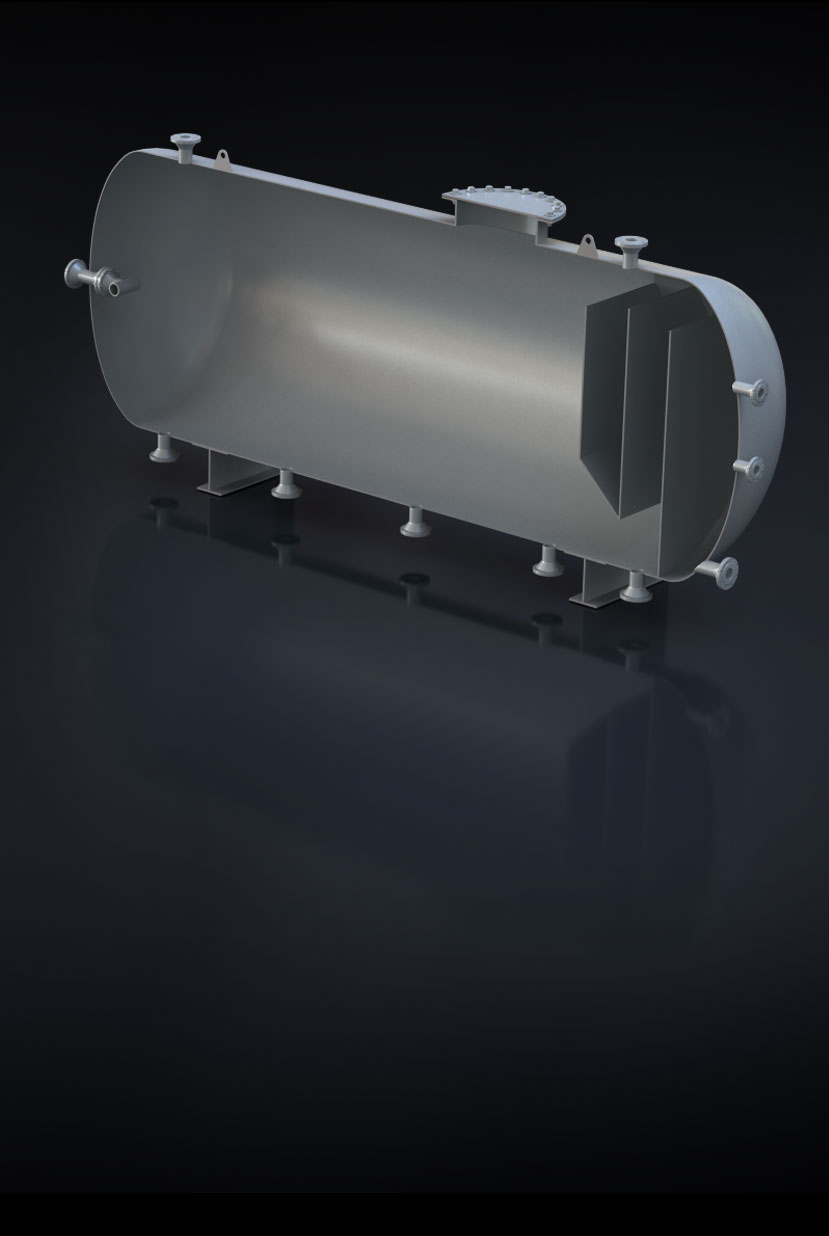

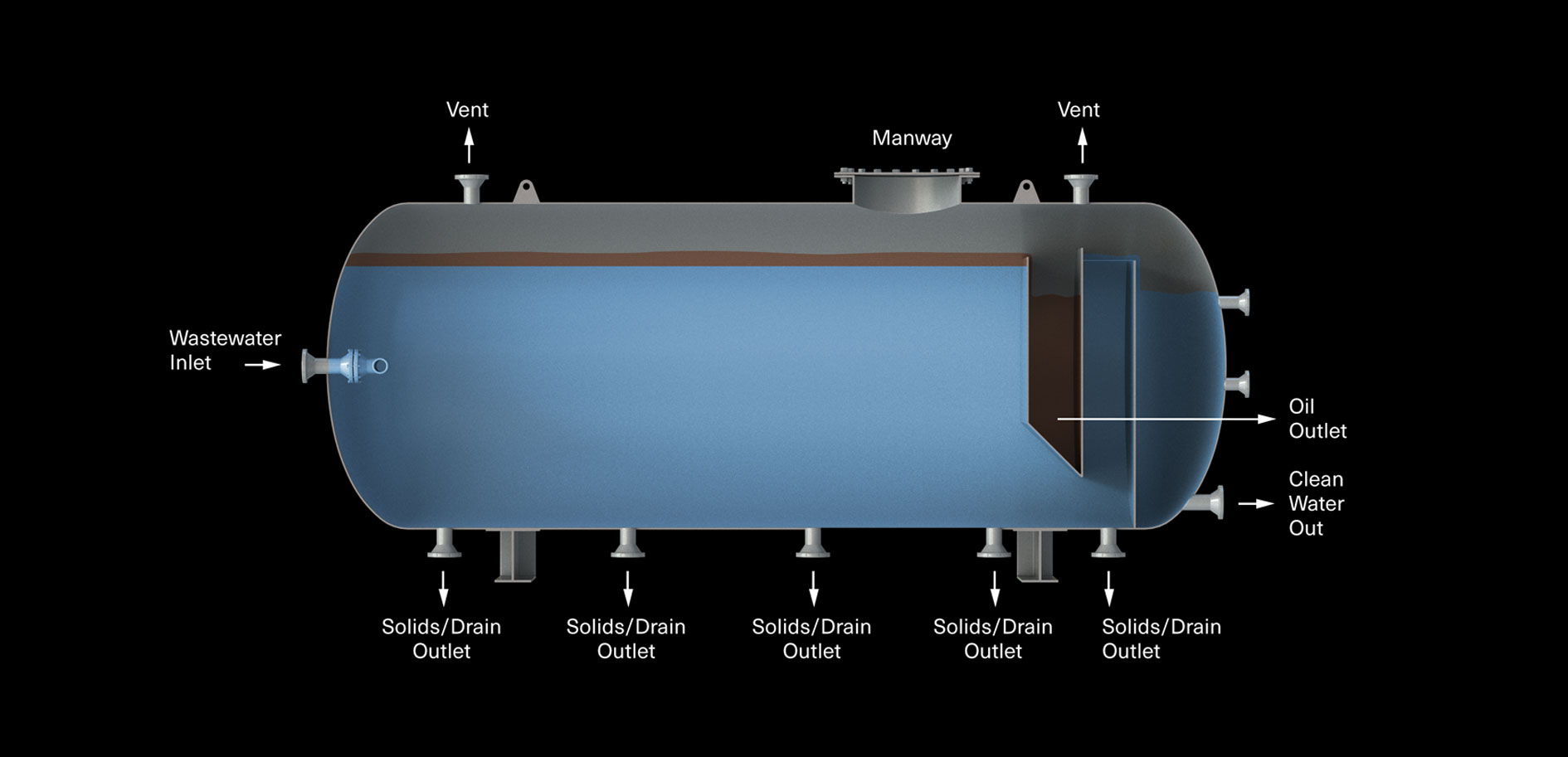

The simplest form of primary treating equipment is a skim tank or vessel. These units, which can be pressure vessels or atmospheric tanks, are normally designed to provide large residence times during which coalescence and gravity separation can occur. Skimmers can be either vertical or horizontal.

Due to the potential danger from overpressure and potential gas venting problems associated with atmospheric vessels, pressure vessels are preferred.

A minimum residence time of 10 to 30 minutes should be provided to assure that surges do not upset the system and to provide for some coalescence. As discussed previously, potential benefits of providing more residence time probably will not be cost efficient beyond this point. CFD studies have shown that skimmer tanks require engineered spreader baffles to properly distribute flow and eliminate short-circuiting

Oil droplets do not have to counterflow the water influent.

Also known as API tank or sump tank.

The principal function of this type of separator is to remove gross quantities of free oil before further treatment. In this capacity, the separator protects more sensitive downstream processes from excessive amounts of contaminant (known as reducing the loading).

Performance will change based on the characteristics of the influent contaminant concentration, specific gravity, particle size and temperature. As a general conservative rule, a 90% reduction in the contaminant can be expected.

Design should be for a 10-30 minute minimum retention time.

In a properly designed separator, any contaminant whose rise rate is greater than the overflow rate will be removed.

Rotatable slotted pipe skimmers or a bucket and weir are used for oil removal.

Water jetting systems can be used to flush solids from the separator.

Above ground designs are preferred due to new EPA regulations.

Maximum performance should be a 100 ppm effluent.

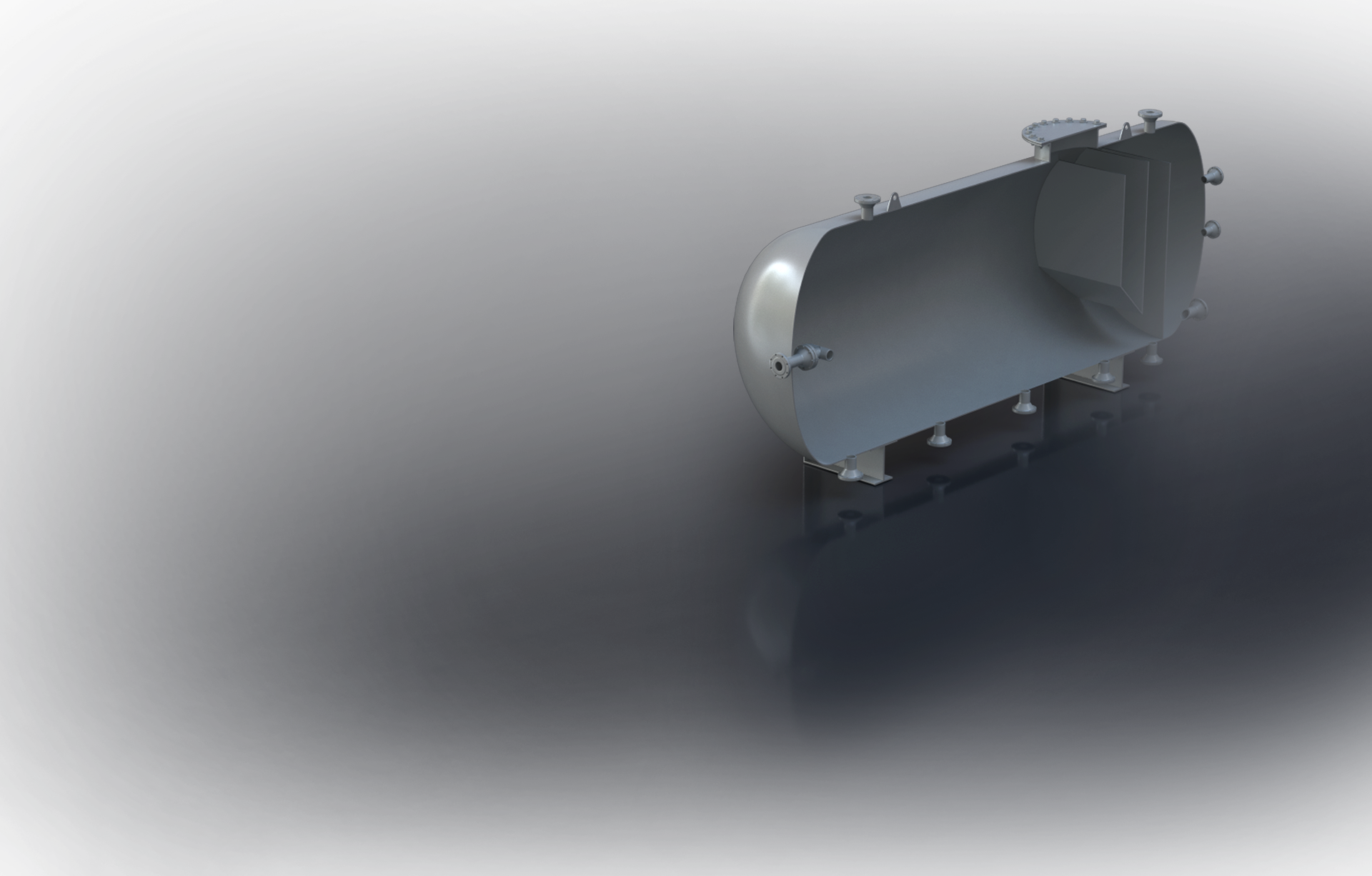

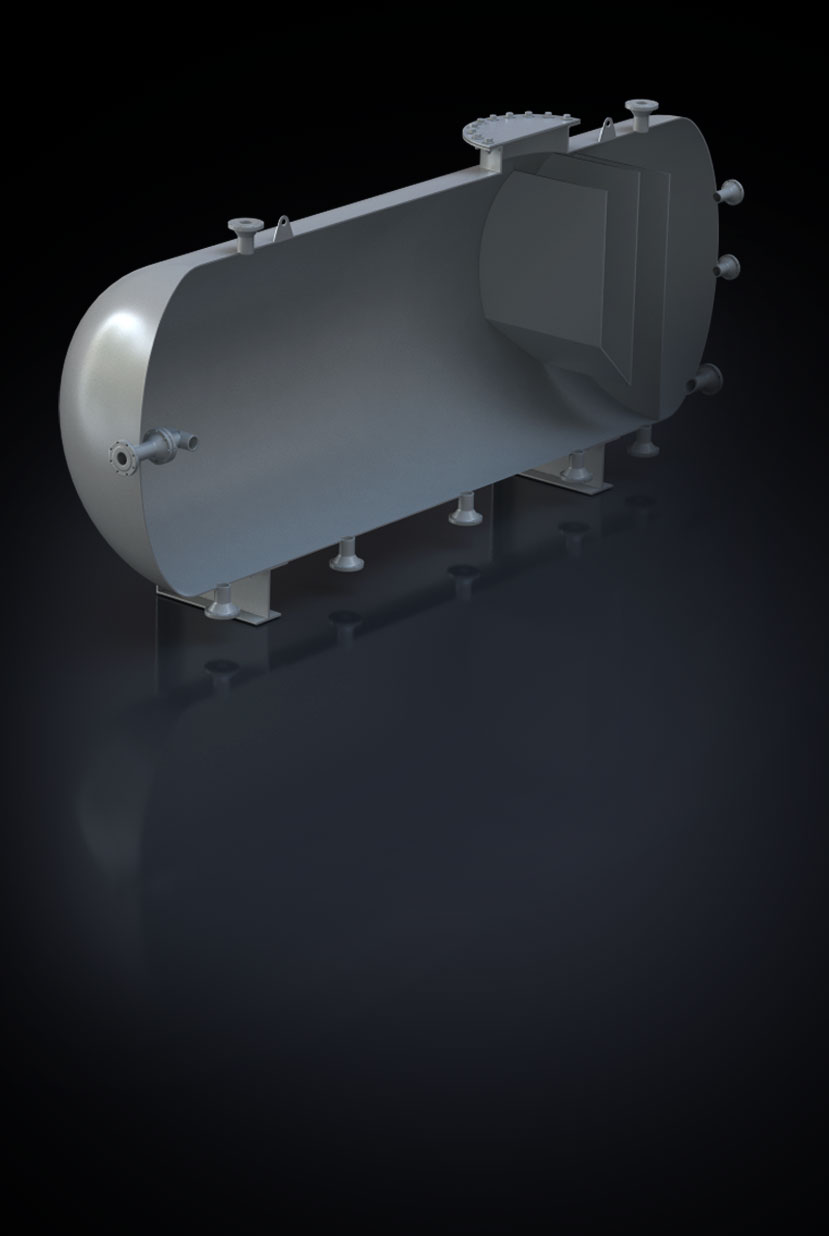

In horizontal skimmers, oil droplets rise perpendicular to water flow as shown. The inlet flows through a downcomerto allow gas breakout and to transport the flow below the oil pad. Water then turns and flows horizontally for most of the length of the vessel. Baffles can be installed to straighten flow. Oil droplets coalesce in this section of the vessel and rise to the surface where they are captured and eventually skimmed over the oil weir. The height of the oil froth can be controlled by interface control or by a bucket and weir design.

Horizontal vessels are more efficient at water treatment because oil droplets do not have to flow counter-current to the water flow.